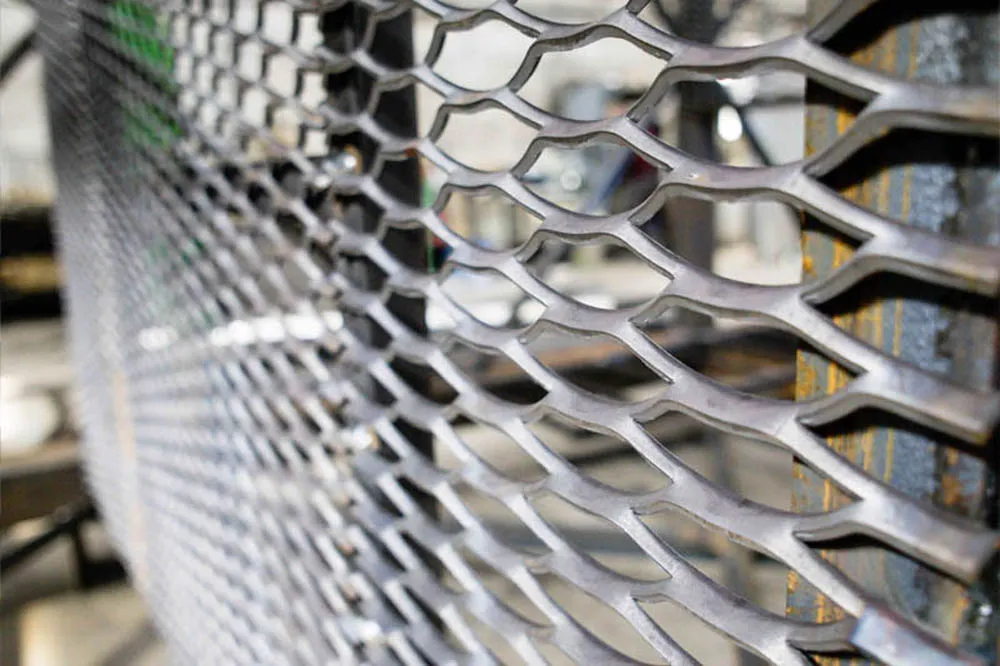

Expanded metal is a versatile material made by cutting and stretching metal sheets to form a mesh-like pattern. The type of expanded metal selected depends on the application, desired strength, aesthetics, and material. Below are some of the most common types:

This type is manufactured from heavier plates, typically low-carbon steel, with larger diamond-shaped openings. It offers high strength and durability, making it ideal for walkways, catwalks, industrial flooring, and platforms where load-bearing capacity and grip are crucial.

Produced by cold-rolling standard expanded metal after the expansion process, this variant results in a smoother, flatter sheet. Flattening also reduces the metal’s original thickness. It’s widely used in architectural applications, enclosures, and machine guards where a smooth finish is essential.

This is the original form of expanded metal, with strands and bonds raised at a uniform angle from the sheet’s plane. This design adds rigidity and provides a skid-resistant surface, ideal for security fencing, ramps, and stair treads.

Specifically designed for architectural and aesthetic purposes, decorative expanded metal is available in various patterns, materials, and finishes. It is used in facades, partitions, and interior design projects and is often specified by brand name. It can be made from aluminum, carbon steel, or specialty alloys.

Featuring smaller and more precise openings, micro expanded metal is used in applications requiring fine filtration, soundproofing, shielding, or detailed screening. It is commonly found in the electronics, aerospace, and medical industries.

Each type of expanded metal serves specific functional or decorative purposes, making it a key material across industrial, commercial, and architectural projects.